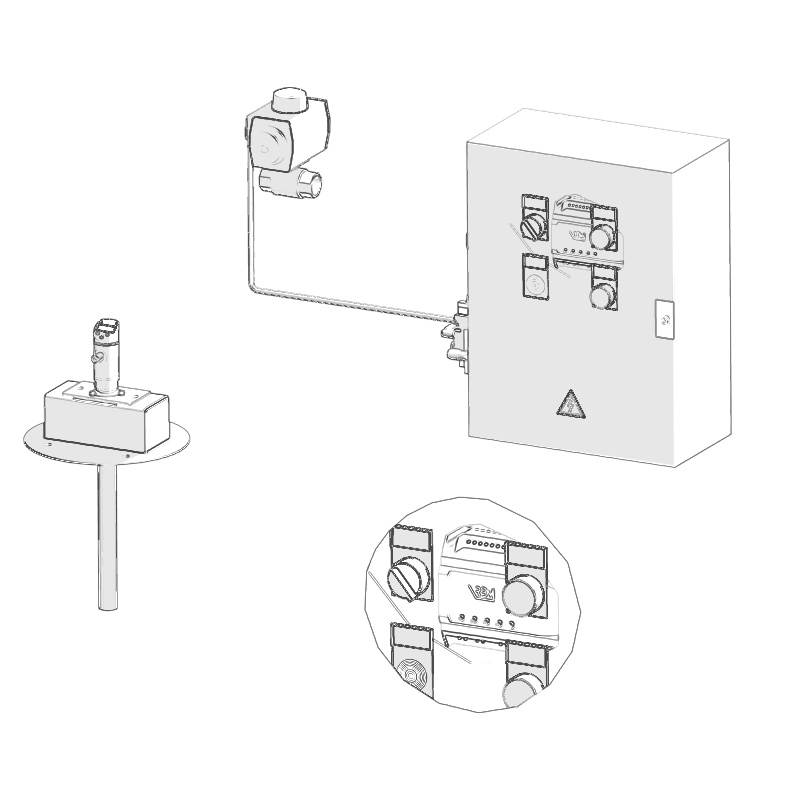

RA-IN Independent automatic coolant top-up

The need to make the machine tools work on unmanned shifts made it necessary to develop a solution to restore the correct level of coolant in the machine tool tanks: the independent automatic coolant top-up. This solution allows maintaining the correct level in the tanks without the risk of cutting fluid dispersion.

The key benefits of using RA-IN are:

- 24 V DC electricity supply, which allows connecting directly to the electrical panel of any machine tool where this voltage is normally present.

- The pneumatic power supply is derived from the one that normally powers the machine tool.

- Internal PLC to manage the top-up thresholds, which can be managed directly by the operator, modifying the required parameters.

- Maximum top-up time, always manageable by the operator, to prevent an electrical fault from causing the coolant in the tanks to overflow for excess topping up.

- Pneumatic valve to open the coolant inflow normally closed. That is, if there is no compressed air or power supply, the top-up will remain closed.

- Level transducer with a complete reading of the coolant present in the tank, without floats or sensors to be regulated, and insensitive to the presence of dirt in the tank.

- Compact containment box easily anchored to the machine tool. As it is closed, only the operator can perform the modification of the operating parameters.

- As an option, it is possible to manage an alarm threshold towards the machine tool to stop the working process in case of anomalies in the coolant tank.

The technology used to read the coolant level and the components employed derives from the consolidated experience of filtration and high-pressure systems produced by RBM.