Workholding Fixtures

Workholding Fixture Specialists

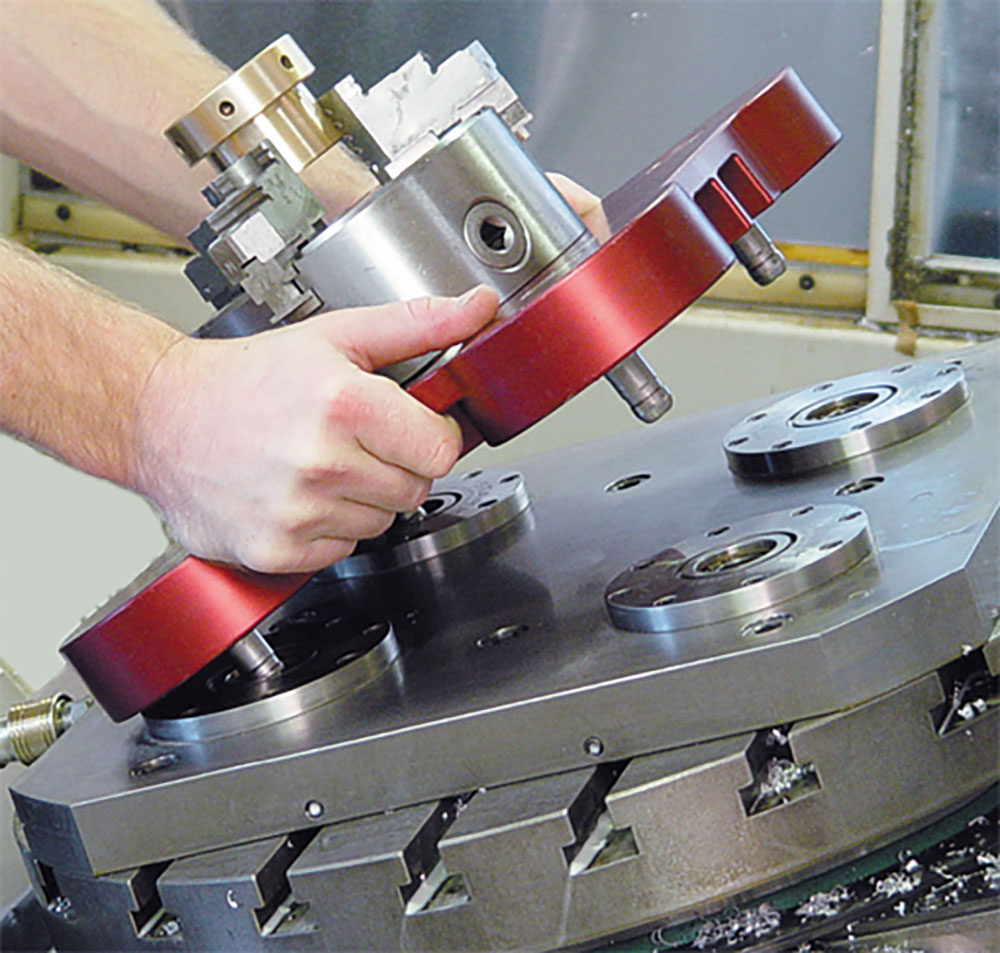

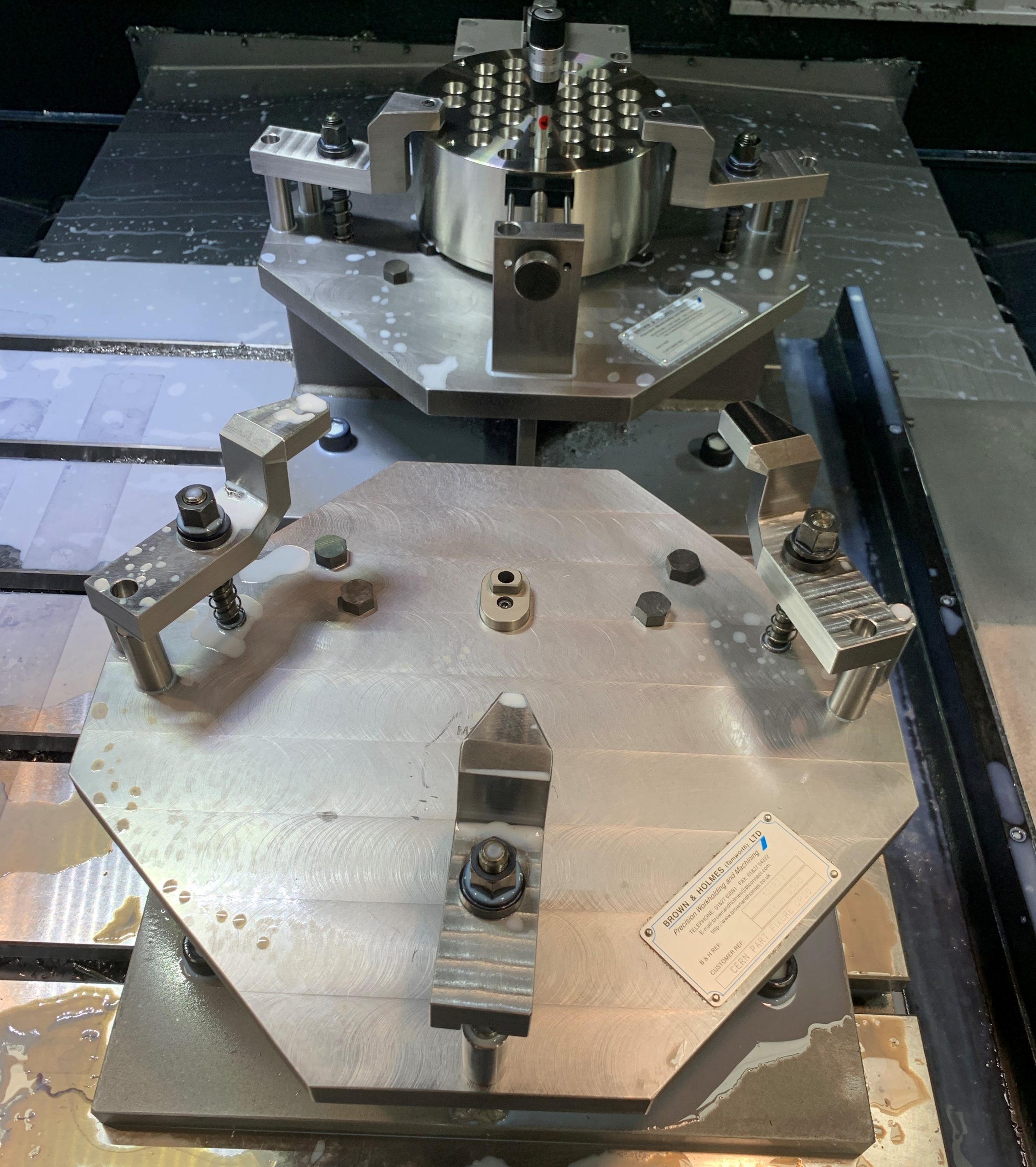

Brown & Holmes Tamworth specialises in the design and manufacture of workholding fixtures, and work with customers within the machine tool, construction, power generation and nuclear industries, offering particular workholding fixture expertise within the automotive and aerospace sectors.

- Skilled in the design and manufacture of aerospace component fixtures and blade fixtures.

- Years of experience in supplying automotive powertrain component work-holding solutions.

- Provision of fully automated, robot-loading work-holding fixtures for blue chip companies and Tier 1 suppliers.

- Ongoing technical support, focused on keeping fixture uptime at 100% by offering a planned servicing programme.

Conveniently located within the Midlands, in the heart of England, we provide installation, service and support to the UK, Ireland, Asia, the Middle East, Europe, Africa and America.

Comprehensive Workholding Fixture Solutions Across Diverse Industries

At Brown & Holmes Tamworth, we specialise in designing and manufacturing a wide range of workholding fixtures tailored to meet the unique requirements of various industries. Our expertise encompasses the creation of precision-engineered fixtures for sectors such as automotive, aerospace, power generation, and construction.

Types of Workholding Fixtures:

- Milling Fixtures: Designed to securely hold workpieces during milling operations, ensuring stability and precision.

- Drilling Fixtures: Engineered to position and support components accurately during drilling processes, enhancing efficiency and accuracy.

- Welding Fixtures: Utilized to maintain the proper alignment of parts during welding, ensuring consistent and high-quality welds.

Workholding Applications and Industry Expertise:

- Automotive Sector: We provide specialised workholding solutions for powertrain components, facilitating efficient and precise manufacturing processes.

- Aerospace Industry: Our fixtures are crafted to meet the stringent standards of aerospace manufacturing, supporting the production of critical components with utmost accuracy.

- Power Generation: We offer fixtures designed for the assembly and maintenance of power generation equipment, ensuring operational reliability.

- Construction: Our workholding solutions assist in the fabrication of construction machinery parts, enhancing production efficiency.

By delivering bespoke workholding fixtures, Brown & Holmes is committed to enhancing manufacturing precision and efficiency across these diverse industries.

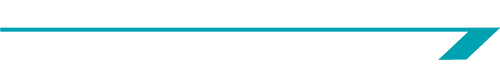

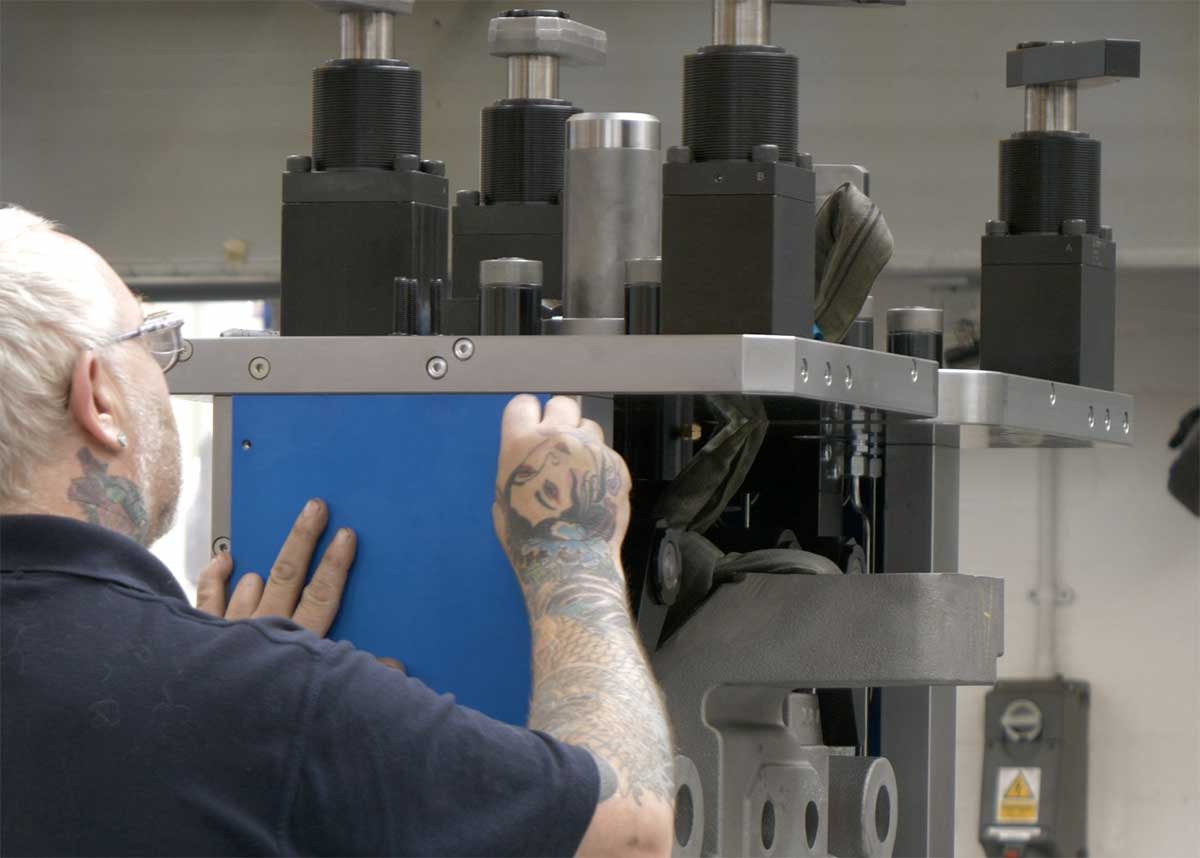

Hydraulic Workholding Fixture

Hydraulic workholding fixtures play a crucial role in precision engineering, providing secure and efficient clamping solutions for machining operations. At Brown & Holmes, we design and manufacture bespoke hydraulic workholding fixtures tailored to the needs of industries such as automotive, aerospace, power generation, and the nuclear sector. Our innovative solutions help manufacturers improve machining accuracy, reduce cycle times, and enhance production efficiency.

By integrating advanced hydraulic clamping mechanisms, our fixtures enable fast, repeatable, and secure workpiece positioning. This results in reduced setup times, improved consistency, and minimised operator intervention—key factors in lean manufacturing. We also develop fully automated hydraulic workholding solutions, including robotic loading systems, to support modern smart manufacturing environments.

Our in-house engineering team utilises the latest CAD/CAM 3D modelling technology to design precision-engineered hydraulic fixtures that maximise stability and accessibility. As a trusted partner to Tier 1 suppliers and blue-chip manufacturers, we ensure that our solutions deliver measurable productivity gains and long-term reliability.

For more information on our hydraulic workholding fixtures and to discuss how we can optimise your manufacturing processes, contact us at info@brownandholmes.co.uk or call 01827 63591.

Further Reading on Hydraulic Workholding and Manufacturing Efficiency

To better understand the benefits of hydraulic workholding and its impact on production efficiency, you may find the following article from the Lean Enterprise Institute valuable:

This article provides valuable insights and examples into how hydraulic workholding can transform manufacturing efficiency, enhance precision, and support automation strategies. You will see good examples of set up reduction times such as Three hours ten minutes to one minute!

Workholding Fixture FAQs

Bespoke workholding fixtures are custom-designed tools made to securely hold and support specific workpieces during machining or assembly processes. They are tailored to fit unique project requirements, ensuring precision and efficiency.

You can contact Brown & Holmes by calling 01827 63591, emailing info@brownandholmes.co.uk, or using the contact form on their website.

Workholding fixtures are devices used in manufacturing to securely hold, position, and support a workpiece during machining or assembly processes. They improve precision and efficiency by keeping the workpiece stable and aligned.

Selecting the appropriate workholding solution depends on factors such as the workpiece material, geometry, machining operations, and production volume. Consulting with experts such as Brown & Holmes Tamworth can help determine the best fit for your needs.

Industries like aerospace, automotive, power generation, manufacturing and construction often require bespoke workholding solutions to meet their specific manufacturing challenges.

When selecting a workholding solution, it’s important to consider factors such as the type of machining operation, the material and shape of the workpiece, production volume, repeatability requirements, and cycle time efficiency. Custom or modular workholding can help maximise productivity and precision.

Yes, Brown & Holmes Tamworth specialises in bespoke workholding solutions tailored to specific manufacturing needs. We work closely with clients across industries like automotive, aerospace, and power generation to design and manufacture workholding fixtures that enhance precision, repeatability, and efficiency.

Dedicated workholding fixtures are designed specifically for a particular workpiece or machining operation, ensuring higher precision, better stability, and reduced setup times.

While standard workholding solutions are flexible and cost-effective, dedicated fixtures can significantly improve quality and efficiency in high-volume production.

Yes, we design workholding solutions that integrate with automated manufacturing processes, including robotic loading systems and CNC machining centres. Our automated workholding solutions help reduce downtime, improve throughput, and maintain consistent quality.

Industries such as aerospace, automotive, medical, defence, and power generation often require bespoke workholding solutions to meet tight tolerances, improve machining accuracy, and streamline production. Our experience across these sectors ensures we can provide the most effective solutions for any application.

The right workholding fixture ensures minimal workpiece movement, faster setup times, and optimal positioning, reducing scrap rates and increasing production speed. Multi-part clamping, quick-change fixtures, and modular designs can further enhance efficiency and flexibility in machining processes.

Yes, we can produce repeat or replacement workholding fixtures for legacy components, ensuring continuity in production and maintaining high precision standards.

Whether you need an exact replica of an existing fixture or an improved design to enhance efficiency, we work with detailed drawings, reverse engineering, and modern manufacturing techniques to provide a seamless solution. Our expertise ensures that even older parts can be securely held and machined to meet ongoing production demands.