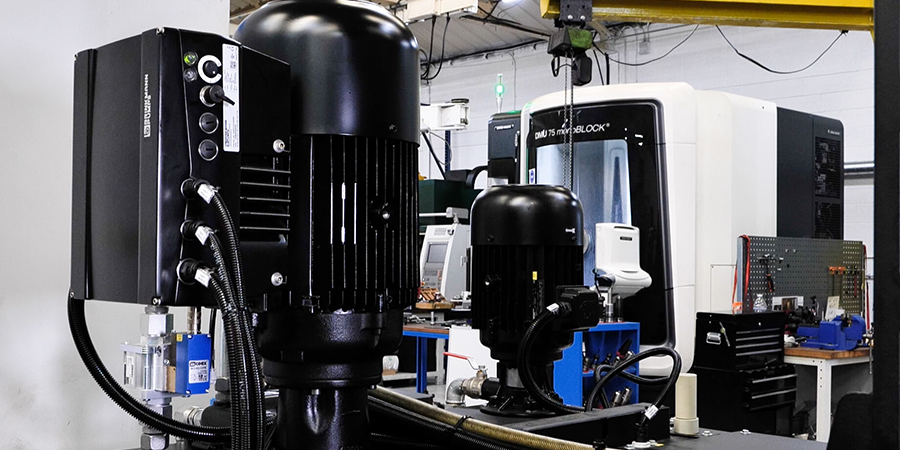

As any engineering or manufacturing company involved in producing high-quality parts knows, maintaining clean coolant is key to a high standard of surface finish (no striation) and maintaining machine tool life. It is about investing in a complete solution, and that means the coolant filtration system, too. Here we discuss the benefits of IFDR systems to your business.

No filter maintenance or frequent coolant replacement costs.

When it comes to coolant filtration, RBM’s IFDR range, distributed by Brown & Holmes has the edge over systems that use paper media. The system does not need standard filtering elements, so filters do not have to be continually replaced, resulting in an immediate reduction in the cost of maintenance. It also prolongs the life of the coolant with the cost savings made by reducing the number of coolant changes.

A better return and improved coolant quality

A recent installation of an IFDR fine filtration system for an aerospace manufacturer resulted in 5 systems working with their machine tools. Within the first 4 months, they had significant returns on coolant costs alone. In addition, before installation, the company had gained 68% compliance on the part, in contrast to an accelerated 96 – 98% compliance post-installation.

Bespoke coolant filtration systems

The IFDR range manages coolant flows of 300, 500, 800 and 1000l, efficiently removing fine chips and grinding sludge to achieve coolant that is clear to 10 microns or less and feeding it back to the machine. However, if larger volume handling is required or, as in a recent case where a single system needed to work with 25 machine tools, a bespoke solution can easily be provided.

Brown & Holmes also provides bespoke engineered fittings for anyone concerned about fitting issues. This is all taken into consideration in the initial survey.

Retrofitting IFDR systems

The IFDR range manages coolant flows of 300, 500, 800 and 1000l, efficiently removing fine chips and grinding sludge to achieve coolant that is clear to 10 microns or less and feeding it back to the machine. However, if larger volume handling is required or, as in a recent case where a single system needed to work with 25 machine tools, a bespoke solution can easily be provided.

Brown & Holmes also provides bespoke engineered fittings for anyone concerned about fitting issues. This is all taken into consideration in the initial survey.

For more information about the IFDR coolant filtration systems, please get in touch on: 01827 63591 or ask a question at https://www.brownandholmes.co.uk/products/rbm/ifdr-systems/