News

Brown & Holmes embraces a future-ready structure

Apprenticeships at Brown & Holmes. Investing in next-generation expertise for an evolving industry. Globally, manufacturers have struggles to recruit the skills they need to maintain high-quality production. In turn, it can become challenging to maintain quality and production levels, which can impact revenue and growth.

Apprenticeships at Brown & Holmes

Apprenticeships at Brown & Holmes. Investing in next-generation expertise for an evolving industry. Globally, manufacturers have struggles to recruit the skills they need to maintain high-quality production. In turn, it can become challenging to maintain quality and production levels, which can impact revenue and growth.

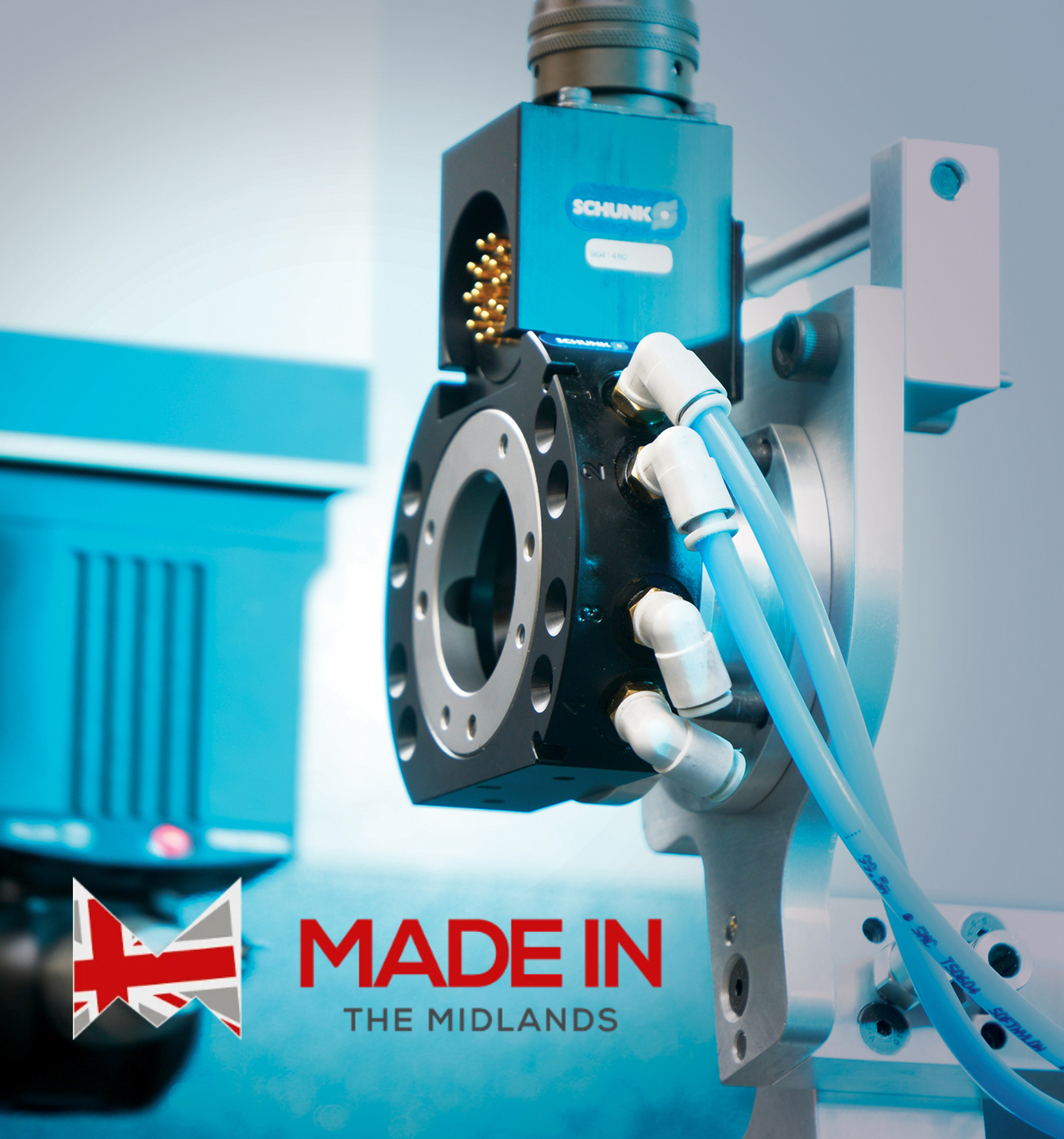

Made in the Midlands

Brown & Holmes, are pleased to announce they have rejoined one of the largest manufacturing groups in the region: Made in the Midlands. As one of the latest members and reinstating the founding membership Brown and Holmes (Tamworth) Ltd, have contributed and supported the organisation since the very start.

Lagun 4-Metre Bed Mill

Versatile, robust and adaptable. The perfect solution for working across multiple industries. Brown & Holmes, a leader in bespoke work holding and fixtures, also serves a substantial client base with subcontract machining. As the industry sees a surge in demand for complex parts and a larger volume of components across diverse sectors, their investment in advanced machinery and skilled workforce positions them as a frontrunner.

Drill jig design and manufacture

The design and manufacture of a complex drill jig require careful thought. Precision, cost, manufacturability, and user-friendliness have to be in balance throughout the process. The business was started in Coventry by Mr Brown and Mr Holmes, two ex-apprentices of Coventry Tool & Gauge, at the outbreak of the Second World War. Because they were a manufacturer and supported the defence effort, the company was soon advised to move away from the area, which was becoming a target for bombing raids.

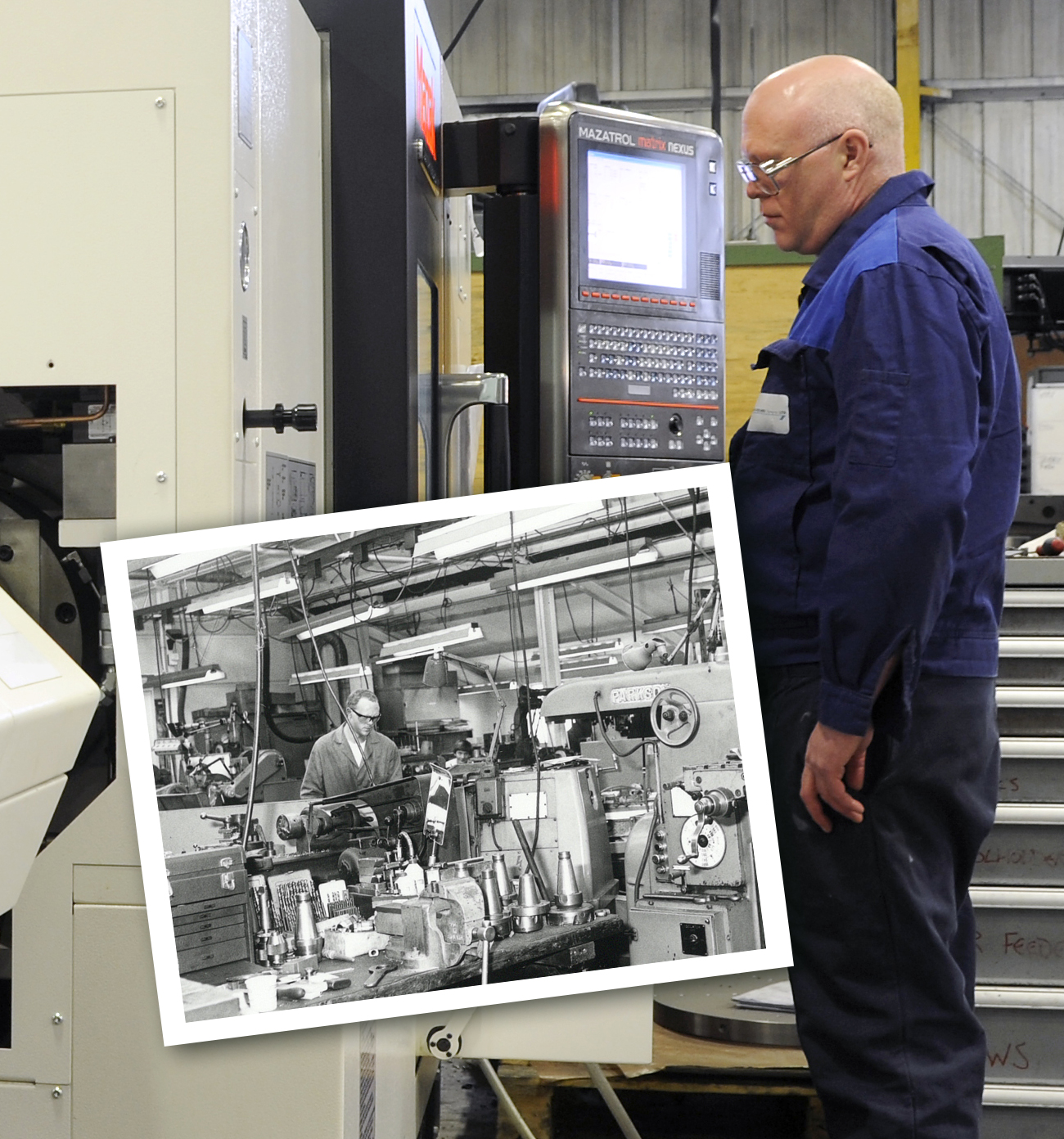

85 years of engineering excellence

Brown & Holmes (Tamworth) Limited has its roots in tradition, innovation, and a steadfast commitment to excellence. Since its inception in 1939, Brown & Homes has met the challenges of some cataclysmic world events, adapting and evolving to become a leader in the delivery of precision machining and subcontract machining solutions. The business was started in Coventry by Mr Brown and Mr Holmes, two ex-apprentices of Coventry Tool & Gauge, at the outbreak of the Second World War. Because they were a manufacturer and supported the defence effort, the company was soon advised to move away from the area, which was becoming a target for bombing raids.

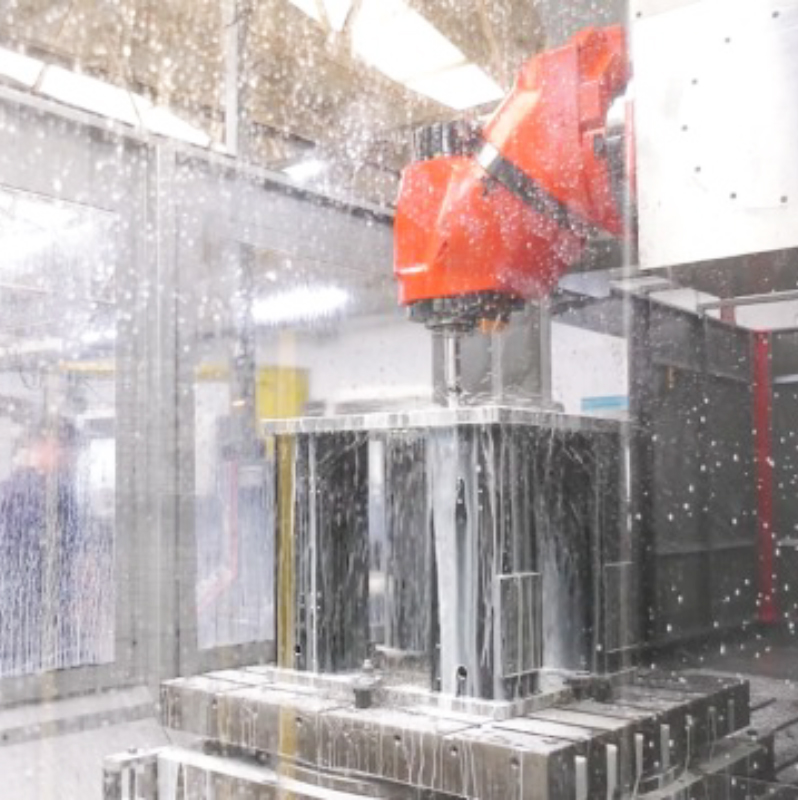

IFDR Coolant Filtration Systems Benefits

IFDR coolant filtration systems great returns on long-term maintenance and product quality. As any engineering or manufacturing company involved in producing high-quality parts knows, maintaining clean coolant is key to a high standard of surface finish (no striation) and maintaining machine tool life. It is about investing in a complete solution, and that means the coolant filtration system, too.

Celebrating Decades of Dedication

Andy’s Journey with Brown and Holmes (Tamworth) Limited, our 85-year legacy is a testament to the dedication, skill, and commitment of our incredible team. Among our many success stories, one stands out for its remarkable journey: Andy joined our company in 1986 and contributed immensely to our success.

Fixturing solution for jet engine turbine manufacturer

Brown & Holmes has an excellent reputation in the design and manufacture of bespoke workholding solutions, much of which they feel has come from their focus on making sure their customers are happy with the end result.

We’ve Joined the Midlands Aerospace Alliance

Joining the MAA, a premier aerospace industry body, underscores Brown and Holmes' commitment to advancing aerospace engineering and innovation in the UK.